Serviços Personalizados

Journal

Artigo

Links relacionados

Compartilhar

Odontoestomatología

versão impressa ISSN 0797-0374versão On-line ISSN 1688-9339

Odontoestomatología vol.26 no.43 Montevideo 2024 Epub 01-Jun-2024

https://doi.org/10.22592/ode2024n43e232

Research

Dimensional stability of irreversible hydrocolloids with conventional pouring and extended-time pouring available in the Uruguayan market

1 Unidad Académica de Materiales Dentales, Departamento de Odontología Preventiva y Restauradora, Facultad de Odontología, UdelaR Autor de correspondencia:Guillermo Grazioli: Gral. Las Heras 1925, Montevideo, Uruguay.ggrazioli@gmail.com

2 Laboratorio Central de Prótesis, Departamento de Rehabilitación Oral y Maxilofacial, Facultad de Odontología, UdelaR.

3 Laboratorio de Materiales Dentales, Área académica de Odontología, Universidad Autónoma del Estado de Hidalgo, México.

Aim

. Compare the dimensional stability of a conventional pouring irreversible hydrocolloid with extended pouring irreversible hydrocolloids.

Methodology.

Four products with extended emptying indication were evaluated: Jeltrate Plus (Denstply Sirona), Hydrogum 5 (Zhermack SpA), Algimax (Major), Kromopan (Lascod) and a conventional emptying product (Tropicalgin; Zhermack SpA). For each product, 10 impressions were made and cast in type III plaster at five different storage times (0, 24, 96, 120 and 168 hours). A three-dimensional model scanner was used to digitize the plaster models and make the corresponding measurements: sum of lengths, dimensional variability, percentage of variability.

Results

. The five commercial brands presented a greater sum of lengths than the control group (p<0,033). At 0, 24 and 96h Tropicalgin and Hydrogum 5 presented significantly less dimensional variation compared to the master model (p<0,001). The variability percentages ranged from 0.24 to 0.91%.

Conclusions.

Dimensional stability depends on the product used. Stored correctly, the conventionally cast irreversible hydrocolloid appears not to undergo significant alterations up to 96h, while in the case of Hydrogum 5 it appears to maintain its dimensional stability up to 168h.

Keywords: Dental impression materials; Alginate; Dimensional stability

Objetivo.

Comparar la estabilidad dimensional de un hidrocoloide irreversible de vaciado convencional con hidrocoloides irreversibles de vaciado extendido.

Metodología.

Fueron evaluados cuatro productos con indicación de vaciado extendido: Jeltrate Plus (Denstply Sirona), Hydrogum 5 (Zhermack SpA), Algimax (Major), Kromopan (Lascod) y un producto de vaciado convencional (Tropicalgin; Zhermack SpA). Con cada producto se realizaron 10 impresiones y se vaciaron en yeso tipo III en cinco tiempos de almacenamiento diferentes (0, 24, 96, 120 y 168 horas). Un escáner para modelos tridimensionales se utilizó para digitalizar los modelos de yeso y realizar las mediciones correspondientes: sumatoria de las longitudes, variabilidad dimensional, porcentaje de variabilidad.

Resultados.

Las cinco marcas comerciales presentaron una sumatoria de longitudes mayor al grupo control (p<0,033). A las 0, 24 y 96h Tropicalgin e Hydrogum 5 presentaron significativamente menor variación dimensional en comparación con el modelo maestro (p<0,001). Los porcentajes de variabilidad oscilaron entre un 0.24 a 0.91%.

Conclusiones.

La estabilidad dimensional depende del producto utilizado. Almacenado correctamente, el hidrocoloide irreversible de vaciado convencional parece no sufrir alteraciones significativas hasta 96h, mientras que en el caso de Hydrogum 5 parece mantener su estabilidad dimensional hasta 168h.

Palabras clave: Materiales de impresión dental; Alginato; Estabilidad dimensional.

Objetivo.

Comparar a estabilidade dimensional de um hidrocolóide irreversível de vazamento convencional com hidrocolóides irreversíveis de vazamento prolongado.

Metodologia.

Foram avaliados quatro produtos com indicação de vazamento estendido: Jeltrate Plus (Denstply Sirona), Hydrogum 5 (Zhermack SpA), Algimax (Major), Kromopan (Lascod) e um produto de vaziamento convencional (Tropicalgin; Zhermack SpA). Para cada produto foram feitas 10 impressões e vazadas em gesso tipo III em cinco tempos de armazenamento diferentes (0, 24, 96, 120 e 168 horas). Um scanner de modelos tridimensionais foi utilizado para digitalizar os modelos de gesso e fazer as medições correspondentes: soma dos comprimentos, variabilidade dimensional, percentagem de variabilidade.

Resultados.

As cinco marcas comerciais apresentaram somatório de comprimentos maior que o grupo controle (p<0,033). Nos tempos 0, 24 e 96h Tropicalgin e Hydrogum 5 apresentaram variação dimensional significativamente menor em comparação ao modelo Mestre (p<0,001). Os percentuais de variabilidade variaram de 0,24 a 0,91%.

Conclusões.

A estabilidade dimensional depende do produto utilizado. Armazenado corretamente, o hidrocolóide irreversível de vaziamento convencional convencionalmente parece não sofrer alterações significativas até 96h, enquanto no caso do Hydrogum 5 parece manter sua estabilidade dimensional até 168h.

Palavras-chave: Materiais de moldagem dentária; Alginato; Estabilidade dimensional

Introduction

Irreversible hydrocolloids (IH), or alginates, are widely used impression materials in dental practice.1 They are employed to create primary, study, or diagnostic models. (2 These materials offer ease of handling without requiring specific equipment and provide a satisfactory cost-benefit ratio. Upon setting, they form a gel-like structure with high water content, influencing their behavior to exhibit a degree of hydrophilicity. 3 This also contributes to their final properties, allowing for acceptable reproduction of details in humid environments, provided the manufacturer's instructions are followed. 3

However, regarding dimensional stability (DS), defined as the ability of a material to maintain its shape and volume over time, recent publications suggest that the DS of this type of material is inferior to other impression materials such as elastomers. 3 The DS of IH is a relevant topic widely discussed in the literature. (2-4 Some studies evaluating DS emphasize syneresis and imbibition as the main factors responsible for poor material performance, particularly after 24 hours. (3

Impression dimensions are influenced by various factors, including the composition of the material, storage conditions, and the duration of storage before pouring. 1 To prevent distortion, it is generally recommended to pour the impressions immediately or within 1 hour after taking them. (1,3-5 However, immediate pouring is not always feasible, especially when impressions need to be sent to the dental laboratory. (2,6

For all these reasons, a new generation of IHs has recently been introduced to the market. These IHs have an indication for extended pouring and are capable of maintaining their DS for 4 to 7 days after the impression is taken.1,6 Despite these claims, studies evaluating DS in extended-pour IHs use different methodologies, leading to contradictory results.1,3,7-9) The lack of a standardized technique to study the effect of time on DS makes it challenging to provide clear recommendations for the use of this type of material. 5,10

In 2014, a method for analyzing DS using digital technology was published, providing greater reproducibility in the methodology. 2

In light of the foregoing, this study aimed to analyze the DS of extended-pour IH and compare it with that of a conventional IH using digital analysis methodology.

Methodology

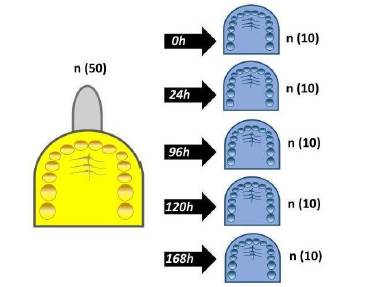

An in vitro, experimental, and longitudinal study was conducted. Four products available in the Uruguayan market with an indication for extended pouring were selected, as well as one with conventional pouring as reference (Table 1). For each product, 10 impressions were made, which were poured at different time intervals: 0 hours (immediate), 24 hours (1 day), 96 hours (4 days), 120 hours (5 days), and 168 hours (7 days). The sample size was determined based on the mean difference from a previous study 3, with a 95% confidence interval and 80% power.

Standardization of Impressions

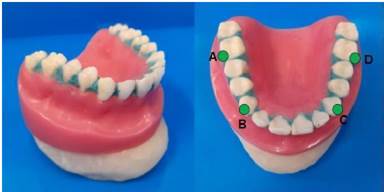

Following the previously described protocol, 2 a device was crafted using an articulator to replicate clinical conditions and standardize impression procedures (Fig. 1). A master model of an upper dental arch with 14 teeth in acrylic resin was employed. Reference marks were created on the cusps of the canines (13, 23) and on the mesiobuccal cusps of the first molars (16, 26) for measurements. To ensure precision and correct tray positioning during impression-taking, standardized positioning was achieved by constructing a polymethylmethacrylate seat/base attached to the underside of the device; this provided a snug fit and ensured reproducibility of the impression-taking procedure. Perforated plastic stock trays of the same size were employed for all procedures.

Fig. 1 Representation of the device crafted for standardizing impressions. A) Continuous-link antagonizing device (articulator). B) Acrylic master model attached to the upper branch of the device. C) Plastic stock tray. D) Acrylic base tailored to the size of the tray, allowing for its stabilization and removal.

Impression Procedure

The master model was mounted on the upper part of the articulator. The impression materials were prepared according to the manufacturer's instructions and handled by a single operator. Immediately after mixing, the irreversible hydrocolloid was placed in the tray. The upper part of the occluder was lowered until the stem contacted the incisal plate. To compensate for the delayed setting time of the material at room temperature -compared to the oral cavity temperature-, the recommended setting time was increased to 5 minutes for all materials used.

After the setting process, the model was swiftly separated from the impression. The impression was then promptly placed into an airtight nylon bag, containing a sheet of paper moistened with 5 ml of distilled water. It was placed in the bag 10 minutes prior to the impression. The paper was positioned in direct contact with the tray, not the impression material. The impressions were stored at 23°C for the predetermined times before being accordingly poured with type III plaster. No rinsing with water nor immersion in any disinfectant solution was carried out for the impressions. Prior to each new impression, the acrylic resin master model was thoroughly cleaned to eliminate any remnants of set material. Additionally, it was immersed in distilled water at 24°C for 5 minutes to prevent potential distortion due to thermal expansion.

According to each commercial brand, 5 subgroups (n=10) were established based on the storage time (0, 24, 96, 120, and 168 hours). This resulted in a total of 50 impressions per group (Refer to Fig. 2). The digitization of the acrylic master model served as the control group for measurement and comparison with the other groups (plaster models poured at different time intervals).

The sample size of n=10 was determined based on statistical calculations for mean difference, relying on the results of a previous study with a similar methodological design, 11) and using the OpenEpi website (www.openepi.com) as the tool for calculation.

Pouring Procedure

Impressions were retrieved from storage based on their respective groups. Models were crafted using Durguix type III high-resistance dental stone plaster (Protechno; Girona, Spain), employing a vacuum mixer (Whip-Mix Corporation, Model D; Louisville, KY, USA), and a Drillco vibrator (Buenos Aires, Argentina), following the manufacturer's instructions. After the recommended setting time, models were removed from the poured impressions, with a 24-hour interval before measurements to allow complete volumetric expansion of the plaster during setting. 12,13 A total of 250 type III plaster models were created.

All materials were used with a minimum margin of 6 months before their expiration date.

Production and measurement of digital models

A Ceramill Map 600 benchtop scanner (Amann Girrbach AG, Koblach, Austria) was utilized to digitize the 250 type III plaster models. Measurements were conducted using Ceramill Mind v4.4 software (Amann Girrbach AG, Koblach, Austria). The four points previously mentioned (A, B, C, and D) were employed to derive four linear measurements (A-B, B-C, C-D, and D-A) (Fig. 3).

Variables Evaluated

Sum of the lengths: the average of the sum of the four linear measurements (A-B, B-C, C-D, and D-A) was assessed in the models obtained from each commercial brand of alginate for each pouring time. These values (in millimeters) were recorded and tabulated for statistical analysis.

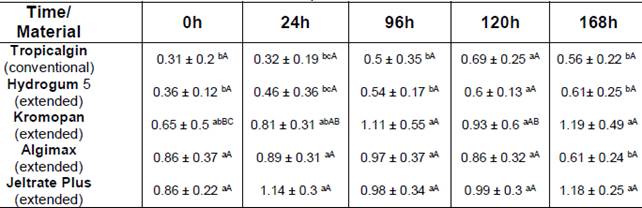

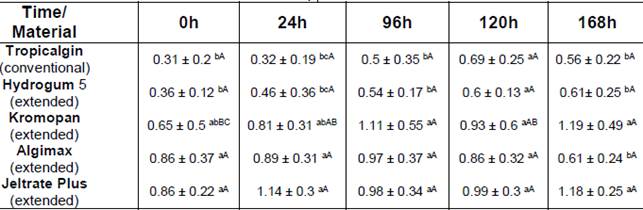

Dimensional Variability: this sum was utilized to compute the deviation from the sum of the four linear measurements of the master model (control). The differences obtained were analyzed through a 2-way ANOVA, yielding the dimensional variability (in millimeters) of the impressions compared to the master model (See Table 2).

Percentage of Variability: The obtained variability values were employed to evaluate this percentage considering the total dimensions and using the master model as a 100% reference (See Table 3). The differences obtained were analyzed through a 2-way ANOVA.

SigmaPlot v12.0 software was utilized for the statistical analyses. It was preceded by a normality test, with a power of 80% and a significance level of 5% established for all analyses.

Results

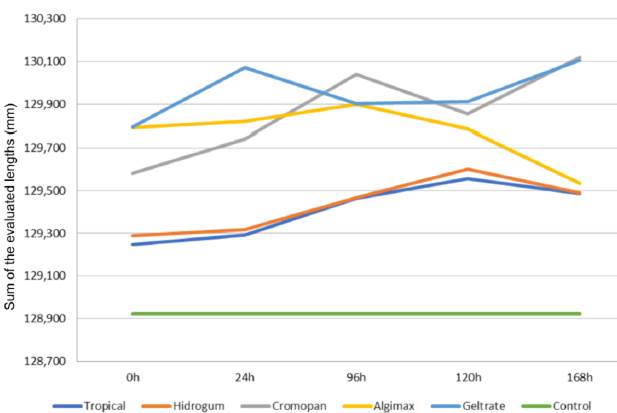

Sum of the lengths

When comparing pouring times and commercial brands at 0, 24, and 96h, Tropicalgin and Hidrogum 5 exhibited significantly lower values compared to Algimax and Jeltrate Plus (p=0.033). In comparison to Kromopan, no differences were found at 0 and 24h, but there were differences at 96h (p=0.001). At 120h, no differences were found between the sums of all the commercial brands (p=0.27). At 168h, Tropicalgin, Hidrogum 5, and Algimax exhibited significantly lower values compared to Kromopan and Jeltrate Plus (p=0.001).

In the intramaterial analysis, Tropicalgin and Hidrogum 5 exhibited no differences between the sums of the evaluated lengths at all time points (p=0.105). Kromopan exhibited differences between 0h and the groups poured at 96 and 168h (p=0.02); however, no significant differences were found between 0, 24, and 120h (p=0.084). Algimax and Jeltrate Plus did not exhibit differences between the sums of the evaluated lengths at all time points (p=0.106).

Dimensional Variability

When comparing pouring times and commercial brands at 0, 24, and 96h, Tropicalgin and Hidrogum 5 exhibited significantly lower values compared to Algimax and Jeltrate Plus (p=0.028). In comparison to Kromopan, no differences were found at 0h (p=0.194), but there were differences at 24 and 96h (p=0.023). At 120h, no significant differences were found among the dimensional variations of all commercial brands (p=0.121). At 168h, Tropicalgin, Hidrogum 5, and Algimax exhibited significantly lower values compared to Kromopan and Jeltrate Plus (p=0.001).

In the intramaterial analysis, Tropicalgin, and Hidrogum 5 exhibited no differences in the sum of the evaluated lengths at all time points (p=0.227). However, Kromopan exhibited differences between 0h and the groups poured at 96 and 168h (p=0.019); however, no significant differences were found between 0, 24, and 120h (p=0.273). Algimax and Jeltrate Plus did not exhibit differences in the sum of the evaluated lengths at all time points (p=0.66).

Percent Variance

Tropicalgin exhibited values ranging from 0.24 to 0.53%. Hydrogum 5 exhibited values ranging between 0.28 and 0.47%. Kromopan 5 exhibited values ranging from 0.51 to 0.92%. Algimax exhibited values ranging between 0.47 and 0.75%. Jeltrate Plus exhibited values ranging from 0.68 to 0.91%.

Discussion

This in vitro study aimed to analyze the dimensional stability of a conventional and an extended-pour IH at different pouring times (0, 24, 96, 120, and 196h). The results suggest lower linear expansion and variability compared to the master model for the commercial brands Tropicalgin and Hydrogum 5 at 0, 24, and 96 hours, with no observed differences in either variable evaluated at 120 hours. However, at 168 hours, Tropicalgin, Hydrogum 5, and Algimax exhibited lower expansion and variability compared to Kromopan and Jeltrate Plus. The analyzed products showed a variability percentage with respect to the master model ranging between 0.24 and 0.92%

Upon analyzing the sum of the dimensions for each commercial brand, the results suggest that Tropicalgin and Hydrogum 5 commercial brands exhibited lower values. No differences were found among all the commercial brands at 120 hours. Similarly, no differences were observed between Tropicalgin, Hydrogum 5, and Algimax at 168 hours. These data could be useful to observe whether the material presents linear expansion or contraction: values lower than the sum of the master model represent contraction, while higher values represent expansion (see Fig 4). Therefore, we can say that Tropicalgin and Hydrogum 5 exhibited lower expansion compared to the control group (see Table 2). Hydrogum 5 has also been recommended for pouring after 120 hours as it showed adequate DS. 1,14,15 Conversely, immediate pouring has been suggested for Tropicalgin (conventional). 1) As far as we know, it is noteworthy that this study is the first to evaluate the DS of alginates at 168h (7 days), since most studies have selected a maximum pouring time of 120h (5 days). 1,14

Other studies have reported that both types of materials show adequate DS when immediate pouring is performed. 16,17 However, after 24h, conventional pouring IHs show low DS compared to extended-pour IHs (18,19, contrary to the findings observed with Tropicalgin (conventional) in this study. Some extended-pour IHs do not show DS differences among themselves in prolonged storage periods (48, 72, 96 and 120h), where it remains constant. However, such DS is lower when compared with the control group (immediate pouring), 15,20, suggesting that the behavior depends largely on the commercial brand used.

All materials evaluated in this study showed a tendency towards expansion of the linear measurements evaluated, similar to findings in other studies (20-22. Several factors have been mentioned in the literature that could compromise the DS of impression materials.16,23,24 Due to their high aqueous content, IHs undergo spontaneous imbibition and syneresis phenomena. These dimensional changes may be influenced by storage conditions; 25 in this study, the impressions were stored in airtight bags with a humid paper, possibly favoring liquid absorption. Conversely, it has been suggested that IHs poured at later time points may also experience volumetric contraction.3,8,22 In these cases, the impressions were stored in hermetic bags without humidity. (17,26 Therefore, the observed increase in the evaluated measurements in this study could be due to humid storage, and differences in the amount of liquid used may also influence the final stability of the material. Nevertheless, the method of storing the impressions hermetically with relative humidity continues to be the most recommended. 9,15

Noteworthy is the behavior observed in the commercial brand Algimax at 168 hours. It was the only material that exhibited a decrease in its dimensions, with no statistical differences compared to Hydrogum and Tropicalgin. During the other periods evaluated, Algimax exhibited greater variations compared to these two materials. Additionally, it is worth noting that the latter commercial brands exhibit a similar behavior; their longitudinal variations are smaller and more constant, suggesting a “more stable” behavior over time (see Fig. 4). Although one product is intended for conventional pouring and the other for extended pouring, such behavior could be attributed to the fact that they share the same manufacturer and perhaps similar composition. It has been reported that extended-pour IHs have a higher calcium/sodium ratio, lower organic content, and higher powder/liquid ratio, which leads to greater crosslinking between the alginate chains. This results in less water loss and thus improved DS. (27

When analyzing variability against the master model, data suggest significantly lower values for the Tropicalgin and Hydrogum 5 commercial brands at 0, 24, and 96h compared to the other brands, with no differences observed at 120h between groups. In turn, at 196h, less dimensional variability was observed between Tropicalgin, Hydrogum 5, and Algimax compared to the other groups. These findings align with those reported for the sum of lengths, suggesting that lower expansion corresponds to reduced length variability compared to the control group (master model).

Studies currently available in the literature utilize different models to evaluate the DS of IHs, which complicates value comparisons, 5,27,28) particularly when analyzing "p" values. Most studies use millimeters (mm) as the unit of measurement. 1,4,29) As such, variations between the master model and models poured at different time intervals can range up to 0.9 mm, as reported in the literature.1 In this study, cumulative deformation values ranging from 0.31 to 1.19 mm are reported (see Table 3).

For this reason, some authors prefer to express dimensional variability in percentage (%).7,10,20 In this study, the percentages of variability range between 0.24% and 0.92%, as reported in several studies. 8,10 However, IH standards (ISO 21563:2021) do not specify a maximum accepted variability value. As a result, some authors suggest referring to printing elastomers standards, where a value of 0.5% is recommended. This value represents the average between 0.4% and 0.6%, the maximum value set for polysulfides and printing silicones, respectively. (31,32 Considering the aforementioned, we can conclude that the commercial brands complying with this recommendation are Tropical (0, 24, 96, 168h), Hydrogum 5 (0, 24, 96, 120, 168h), and Algimax (168h) (See Fig. 5).

Other authors have mentioned a maximum variability value of 5% (equivalent to 95% elastic recovery). (9 With this consideration, we can state that all the products evaluated in this study meet the established requirements. The use of plaster models becomes debatable when the impression material exhibits significant deformations. However, as suggested, there should be no issues in diagnostic works, primary models, myorelaxant plates, bleaching procedures, etc.10,26 Nonetheless, it's essential to establish a maximum threshold value to deem an impression suitable for precision-demanding tasks. Therefore, further studies focusing on the clinical performance of treatments are warranted to provide evidence for in vitro studies. In line with this, a clinically acceptable marginal discrepancy range for resin and ceramic restorations has been determined to be between 27 and 83 μm (0.08 mm).8

Finally, it's worth noting that other factors linked to dimensional variations in IHs include the operator, water temperature, working environment, measurement methodology, and the type/brand of the pouring material. This is because plaster might undergo expansion during setting, which could, in some instances, compensate for distortions caused by the impression material. 8,25,33,34) Regarding the limitations of this study, it is important to acknowledge its in vitro nature, which makes it challenging to extrapolate the data to a clinical setting. Additionally, the selected methodology for evaluating DS presents data at a longitudinal/linear level rather than volumetric, and only a limited number of commercial brands were analyzed. Future studies should advocate for standardized methodologies in DS evaluation, establish a maximum accepted threshold value for IH deformation, and assess the influence of other aforementioned factors, such as impression storage medium.

Conclusions

Based on the limitations of this in vitro study, we can conclude that dimensional stability depends on the product used. When stored correctly, the conventional pouring irreversible hydrocolloid does not appear to undergo significant alterations up to 96 hours. In the case of Hydrogum 5, it seems to maintain its dimensional stability up to 168 hours. All commercial brands showed a tendency to expand. The authors emphasize the importance of handling the materials according to the manufacturers' instructions.

The entire dataset supporting the findings of this study was published within the article itself.

Acknowledgments

The authors express their gratitude to the following companies: Sudenco, Ergon Dental, Dental Latina, Dental Link, and Dental Castro for their donation of the alginates and plasters used in the execution of this work

REFERENCES

1. Rohanian A, Ommati Shabestari G, Zeighami S, Samadi MJ, Shamshiri AR. Effect of storage time of extended-pour and conventional alginate impressions on dimensional accuracy of casts. J Dent (Tehran Univ). 2014;11(6):655-64. [ Links ]

2. Gümüs HÖ, Dinçel M, Büyük SK, Kilinç HI, Bilgin MS, Zortuk M. The effect of pouring time on the dimensional stability of casts made from conventional and extended-pour irreversible hydrocolloids by 3D modelling. J Dent Sci. 2015 Sep;10(3):275-81. DOI: 10.1016/j.jds.2014.05.003 [ Links ]

3. Garrofé AB, Ferrari BA, Picca M, Kaplan AE. Linear Dimensional Stability of Irreversible Hydrocolloid Materials Over Time. Acta Odontol Latinoam. 2015;28(3):258-62. [ Links ]

4. Vaz da Costa R, Silva Valente M, Soares Da Rocha S. Analysis of the Dimensional Stability of Extended-Storage Irreversible Hydrocolloids. Rev Odontol Bras Cenntral. 2017;26(76):7-10. [ Links ]

5. Nassar U, Aziz T, Flores-Mir C. Dimensional stability of irreversible hydrocolloid impression materials as a function of pouring time: A systematic review. J Prosthet Dent. 2011 Aug;106(2):126-33. DOI: 10.1016/S0022-3913(11)60108-X [ Links ]

6. Aalaei S, Ganj-Khanloo R, Gholami F. Effect of Storage Period on Dimensional Stability of Alginplus and Hydrogum 5. J Dent (Tehran). 2017;14(1):31-9. [ Links ]

7. Todd JA, Oesterle LJ, Newman SM, Shellhart WC. Dimensional changes of extended-pour alginate impression materials. Am J Orthod Dentofac Orthop. 2013 Apr;143(4):S55-63. DOI: 10.1016/j.ajodo.2012.06.016 [ Links ]

8. Imbery TA, Nehring J, Janus C, Moon PC. Accuracy and dimensional stability of extended-pour and conventional alginate impression materials. J Am Dent Assoc. 2010 Jan;141(1):32-9. DOI: 10.14219/jada.archive.2010.0018 [ Links ]

9. Rodrigues SB, Augusto CR, Leitune VCB, Samuel SMW, Collares FM. Influence of delayed pouring on irreversible hydrocolloid properties. Braz Oral Res. 2012 Oct;26(5):404-9. DOI: 10.1590/S1806-83242012000500005 [ Links ]

10. Choudhary S, Sivakumar I, Buzayan M, Choudhary P. Dimensional accuracy of double poured casts obtained from extended pour alginate impressions: An in vitro study. J Int Oral Heal. 2018;10(6):272. DOI: 10.4103/jioh.jioh_199_18 [ Links ]

11. Cesur M, Omurlu I, Ozer T. Evaluation of digital model accuracy and time-dependent deformation of alginate impressions. Niger J Clin Pract. 2017;20(9):1175. DOI: 10.4103/1119-3077.197012 [ Links ]

12. Luthardt RG, Kühmstedt P, Walter MH. A new method for the computer-aided evaluation of three-dimensional changes in gypsum materials. Dent Mater. 2003 Jan;19(1):19-24. DOI: 10.1016/s0109-5641(02)00013-1 [ Links ]

13. Michalakis KX, Asar NV, Kapsampeli V, Magkavali-Trikka P, Pissiotis AL, Hirayama H. Delayed linear dimensional changes of five high strength gypsum products used for the fabrication of definitive casts. J Prosthet Dent. 2012 Sep;108(3):189-95. DOI: 10.1016/S0022-3913(12)60146-2 [ Links ]

14. Sedda M, Casarotto A, Raustia A, Borracchini A. Effect of Storage Time on the Accuracy of Casts Made from Different Irreversible Hydrocolloids. J Contemp Dent Pract. 2008 May;9(4):59-66. DOI: 10.5005/jcdp-9-4-59 [ Links ]

15. Calmon JDQ, Relvas A, Lefrançois M, Azevedo MV, Sotelo P, Sotelo L. Estabilidade dimensional de moldes obtidos com alginato de armazenamento tardio. Rev Odontol da UNESP. 2019;48. DOI: 10.1590/1807-2577.09819 [ Links ]

16. Hussain MW, Chaturvedi S, Naqash TA, Ahmed AR, Das G, Rana MH, et al. Influence of time, temperature and humidity on the accuracy of alginate impressions. J Ayub Med Coll Abbottabad. 2020;32(Suppl 1(4):S659-67 [ Links ]

17. BITENCOURT SB, CATANOZE IA, SILVA EVF da, TURCIO KHL, SANTOS DM dos, BRANDINI DA, et al. Extended-pour and conventional alginates: effect of storage time on dimensional accuracy and maintenance of details. Dental Press J Orthod. 2021;26(3):1-28. DOI: 10.1590/2177-6709.26.3.e2119251.oar [ Links ]

18. Daneu G, Vasconcelos J, Oltramari P, de Almeida M, Guiraldo R, Fernandes T. Dimensional stability of alginate molds scanned at different storage times. Acta Odontológica Latinoam. 2020 Dec;33(3):221-7. DOI: 10.54589/aol.33/3/221 [ Links ]

19. Bang H, Shim H, Cho Y, Park E. Effect of mixing method and storage time on dimensional stability of alginate impressions materials. J Korean Acad Prosthodont. 2020;58(2):86. DOI: 10.4047/jkap.2020.58.2.86 [ Links ]

20. Kusugal P, Chourasiya R, Ruttonji Z, Astagi P, Nayak A, Patil A. Surface detail reproduction and dimensional stability of contemporary irreversible hydrocolloid alternatives after immediate and delayed pouring. Contemp Clin Dent. 2018;9(1):20. DOI: 10.4103/ccd.ccd_676_17 [ Links ]

21. Walker MP, Burckhard J, Mitts DA, Williams KB. Dimensional change over time of extended-storage alginate impression materials. Angle Orthod. 2010 Nov;80(6):1110-5. DOI: 10.2319/031510-150.1 [ Links ]

22. Muhammed B. E-D, Muhammed A. G, Seham A. H. EXTENDED-STORAGE IRREVERSIBLE HYDROCOLLOID IMPRESSION MATERIALS. Alexandria Dent J. 2016 Aug 1;41(2):146-9. DOI: 10.21608/adjalexu.2016.59269 [ Links ]

23. Ghasemi E, Ebadian B, Asadi A, Ghasemi N. Effects of Water/Powder Ratio of Irreversible Hydrocolloid on Dimensional Stability of Impressions. J Islam Dent Assoc IRAN. 2020 Oct 1;32(3):43-9. DOI: 10.30699/jidai.32.3.4.43 [ Links ]

24. Sharif RA, Abdelaziz KM, Alshahrani NM, Almutairi FS, Alaseri MA, Abouzeid HL, et al. The accuracy of gypsum casts obtained from the disinfected extended-pour alginate impressions through prolonged storage times. BMC Oral Health. 2021 Dec 9;21(1):296. DOI: 10.1186/s12903-021-01649-2 [ Links ]

25. Pal A, Singhal MK, Jha D, Chopra M, Yadav K. Environment to Store Alginate at its Best: An In-vitro Study. J Clin DIAGNOSTIC Res. 2023;17(18):20-3. DOI: 10.7860/JCDR/2023/59033.17595 [ Links ]

26. Alcan T, Ceylanoglu C, Baysal B. The Relationship between Digital Model Accuracy and Time-Dependent Deformation of Alginate Impressions. Angle Orthod. 2009 Jan 1;79(1):30-6. DOI: 10.2319/100307-475.1 [ Links ]

27. Abdelraouf RM. Chemical analysis and microstructure examination of extended-pour alginate impression versus conventional one (characterization of dental extended-pour alginate). Int J Polym Mater Polym Biomater. 2018 Jul 3;67(10):612-8. DOI: 10.1080/00914037.2017.1362636 [ Links ]

28. Potran M, Strbac B, Puskar T, Hadzistevic M, Hodolic J, Trifkovic B. Measurement of the accuracy of dental working casts using a coordinate measuring machine. Vojnosanit Pregl. 2016;73(10):895-903. DOI: 10.2298/VSP150105089P [ Links ]

29. Pinheiro LOB, Ayala AS, Pomini MC, Cruz VT da, Farias IV del, Samra APB. Linear dimensional stability of irreversible hydrocolloids with and without disinfection at different storage times. RSBO. 2019 Jan 25;15(2):77. DOI: 10.21726/rsbo.v15i2.673 [ Links ]

30. International Organization for Standardization. ISO 21563:2021 - Dentistry - Hydrocolloid impression materials (Internet). [ Links ]

31. American National Standards Institute. ANSI/ADA Specification No. 19-2003 - Dental Elastomeric Impression Materials (Internet) [ Links ]

32. Kulkarni MM. Dimensional Changes of Alginate Dental Impression Materials-An Invitro Study. J Clin DIAGNOSTIC Res. 2015;9(8):ZC98-102. DOI: 10.7860/JCDR/2015/13627.6407 [ Links ]

33. Muzaffar D, Braden M, Parker S, Patel MP. The effect of disinfecting solutions on the dimensional stability of dental alginate impression materials. Dent Mater. 2012 Jul;28(7):749-55. DOI: 10.1016/j.dental.2012.03.013 [ Links ]

34. Marquezan M, Jurach EM, Guimarães VD, Valentim RGA, Nojima LI, Nojima M da CG. Does the contact time of alginate with plaster cast influence its properties? Braz Oral Res. 2012 Mar 20;26(3):197-201. DOI: 10.1590/S1806-83242012005000005 [ Links ]

Conflict of Interest The authors of this work declare that there is no potential conflict of interest.

Authorship and collaboration contribution a) Study conception b) Data acquisition c) Data analysis d) Results discussion e) Manuscript drafting and revision f) Approval of the final version of the manuscript AG has contributed to a, d, e, f. MM has contributed to a, b, d, e, f. EL, RT, and PV have contributed to a, d, e. MAG, GS, and SP have contributed to b. RG has contributed to a, b. CCS has contributed to a, c, f. GG has contributed to a, c, d, f.

Received: November 03, 2023; Accepted: March 07, 2024

texto em

texto em