Introduction

Liquid biofuels (biodiesel and bioethanol), biogas (methane), pellets, chips and briquettes made either from Woody or herbaceous materials are one of the most promising sources of renewable energy. Biofuels obtained from sources that could be used for human alimentary purposes, such as sugar cane and corn, are named first generation biofuels and have low acceptance among a large proportion of society and scientific community (Tilman et al., 2009). Therefore, many researchers are studying lignocellulosic alternatives to obtain energy, which are not intended for human consumption. Lignocellulosic biomass could meet a significant proportion of the primary energy global demand (Verón et al., 2012).

Oil prices volatility impacts heavily on the society regarding its shares in production, processing and distribution costs of foods, and the increasing living costs associated with energy consumption at the residential, transport and industry sectors. Furthermore, fossil fuels combustion is one of the main responsibles for raising greenhouse gas (GHG) atmospheric concentration affecting climate change (Camino, Ruggeroni & Sánchez, 2015). Therefore, it is necessary to seek for renewable energy sources with a low environmental impact with a neutral or negative carbon balance in order to meet the optimistic scenario of CO2 for year 2100. These energy sources should also generate growth and development and, if possible, utilize unexploited or unprofitable resources.

The sustained global growth, considering number of inhabitants and gross domestic product per capita, has generated an increase in food intake and energy consumption. The annual world primary energy consumption excedes 500 EJ and is expected to rise by 2100 to 1275-1500 EJ (Reilly & Paltsev, 2008). Among total energy consumption, 35-40 % is obtained from oil. Although proven oil reserves have increased due to new discoveries, when measured relative to annual demand, the relationship between reserves and annual production remained around 40-48 years during the last decades, surpassing 52 years since 2014.

Levine (1991) reported that 1660 Tg of carbon as CO2 are annually released to the atmosphere due to savannas fires contributing to rising GHG concentration which triggers global warming and climate change. Wildfires release not only carbon but also other contaminants such as NOx and SOx, which are stronger GHG than CO2 and can damage respiratory tracts. Furthermore, particulate matter is another contaminant produced by wildfires that can directly affect human health. Hence, policies should encourage fires avoidance in order to lower these negative impacts in the environment and human health. Biomass extraction for an economic purpose in a sustainable manner could be achieved while preventing the negative social and environmental impacts of wildfires. Bioenergy, among all possible alternatives, would generate several positives externalities such as climate change mitigation, increase of employment in undeveloped regions, and energy self-sufficiency.

According to Verón et al. (2012), 36-44 % of global electricity consumption could be met by diverting wildfires to power generation and, specifically in Argentina, such diversion could exceed the national power demand. Feldman, Bisaro & Lewis (2004) reported that fire and clipping promoted photosynthetic rates of S. argentinensis and Sosa (2015) found that harvesting S. argentinensis biomass for bioenergy purposes could contribute to power generation without affecting vegetation, arthropods biodiversity or soil organic carbon.

Herbaceous biomass can be harnessed to obtain energy via biological or thermochemical processes (Figure 1). For most processes biomass conditioning is necessary to facilitate logistic. Densification is crucial and mandatory for long biomass transportation distances from field to biorefinery in order to reduce the economic and energetic costs of this stage. Specific particle size needs to be met for some densification alternatives and moisture content needs to be adjusted to the requirements of the conversion process (i.e: low moisture content is often desired for thermochemical processes).

Gasification is a thermochemical reaction which transforms biomass in a low energy content gas (syngas) suitable for boiler, engine or turbine operation. Syngas can be used in several ways: (i) electricity generation with power generation efficiencies of 20-35 %; (ii) heat production with circa 85 % conversion efficiency, and (iii) cogeneration in a combined heat and power (CHP) plant with 15-35 % and 55 % power and heat efficiency respectively. Moutsoglou (2012) simulated the gasification of Panicum virgatum and Spartina pectinata concluding that the last one would yield a syngas of higher calorific value. Tri-generation technologies have been evaluated successfully in other species of the genus Spartina (Yuping et al., 2007).

Downdraft gasifier is the most common type of gasification technology used in Europe, United States and Canada due to the following advantages: (i) a low power production cost for capacities lower than 2 MW; (ii) production of syngas with low tar content before conditioning; (iii) higher fed size which can be as much as 50 mm (Basu, 2013); (iv) easy construction; (v) simple operation; (vi) high thermal efficiency; and (vii) well adapted for small scale plants, which makes them suitable for decentralized power generation. The latter advantage results vital when considering biomass availability and its low energetic density, even more when the large extension of Argentine and the vast availability of biomass resources all over the country are considered. In this gasifier, biomass is fed from the top and travel downward passing different zones with diffuse limits from the top to the bottom: drying, pyrolysis, combustion and reduction zones. A controlled quantity of air is supplied to the gasifier some height below the top and moves downward as well (Basu, 2013).

The Bajos Submeridionales (Figure 2) of Argentina comprise an extensive area of about 33,000 km2 characterized by halo-hydromorphic soils, with very slow drainage and vegetation characterized by grasslands and savannas. Spartina argentinensis Parodi, the dominant species of the Bajos Submeridionales, is a perennial grass that forms clumps of more than 1 m in diameter and 1.2 to 1.5 m in height, presents high photosynthetic rates even under water stress conditions (Feldman, Bisaro & Lewis, 2004), and continues growing after disturbances such us fire or clipping (Feldman, Bisaro & Lewis, 2004; Feldman & Lewis, 2007).

Despite occupying large areas, the Bajos Submeridionales have a low population density with scarce economic activity. This determines that there is low labour demand in the area (mainly unskilled labour), and there are few services available to local population, most of them of poor quality. Soil and topographical features constrain crop production in the region, hence livestock is the main activity and burning grasslands is a common practice among farmers looking for higher forage quality. In the humid Chaco region between 2 and 4 million hectares are burnt annually (Herrera, Torrella & Adámoli, 2003) releasing between 36 to 72 million Mg of CO2 to the atmosphere (Jozami, Sosa & Feldman, 2003).

Energy availability is a crucial developmental factor for all areas of the economy. In Argentina, after the social and economic crisis in 2001, a high economic growth resulted in increases in energy demand, which was not followed by increases in energy supply. Furthermore, fossil fuel tariff have received strong subsidies further increasing its demand. Accordingly, energy imports (mainly natural gas, which is the main energy source for electricity and heat purposes) have grown steadily since then in order to meet this growing demand, thus generating a negative commercial balance. Besides this economic consequence, several electricity shortages occurred during periods of high consumption in critical summer days, associated with a high electricity demand for air conditioning (Filippin & Flores Larsen, 2009). Subsidy policy has demonstrated serious consequences for the economy and the environment, as it happens in other countries (Lipton, 2013). The fiscal burden of subsidies creates budget deficits that threat the economy stability, and generates negative externalities on the environment due to the greater consumption of fossil energy.

According to González (2009), low prices of subsidized fossil fuels have stimulated low thermal performance of buildings, resulting in higher energy consumption for heating and cooling in the residential sectors. Furthermore, the high quantity of natural gas required for heating in the residential sector during the winter cannot be satisfied without partly shutting off industry supply and liquefied natural gas for transportation (González, 2009).

An important factor to consider from a developer’s point of view, for any investment in renewable energy (RE) power generation, is the selling price of the energy. In order to generate profits, selling price should be higher than the production costs. Garcia-Barberena, Monreal & Sánchez, 2004) propose the Break-Even Price of Energy (BEPE), the selling price of energy that makes the Net Present Value (NPV) equal to zero and is the price threshold over which the project becomes profitable. These authors also suggest that it should be considered by policy makers as well, while designing subsidizing policies for RE power generation and which should ensure selling prices higher than the BEPE.

One indicator of sustainability is the Energy Return On Investment which can be defined as the ratio between the energy obtained from an activity and the energy required for it. Both, the numerator and the denominator must be accounted in the same units. Pimentel (2008) mentioned that the EROI of finding and production of US domestic oil has decreased over the last decades from circa 100 to 11-18 because of the depletion of oil reservoirs and increasing of energy costs for such activities regarding a shift of exploration to deeper and offshore areas.

The aim of this paper is to assess the technical and economic feasibility of exploiting Spartina argentinensis feedstock as a source of pellets to produce electrical and thermal energy through the gasification and syngas cogeneration processes, and to evaluate the energy balance of the proposed system.

Materials and Methods

We developed a model including the following stages depicted in Figure 3: biomass harvest with a self-propelled chopper, shipping to plant, drying and conditioning, pelletizing, pellet storage, and gasification for CHP. Jozami, Sosa & Feldman (2013) reported 10 Mg.ha-1 of aboveground net primary productivity (ANPP) for S. argentinensis grasslands; we considered 60 % of it could be harvestedwith 40 % moisture content. This is a conservative figure considering that Sosa (2015) measured 13.2 Mg of ANPP for the same species.

The model considered 10 km truck transportation to the plant including empty returning. We assumed that biomass was dried with a rotary dryer up to 15 % of moisture, then milled, pelletized, and stored in silos connected to the gasifier through screw conveyors. A downdraft gasifier design of 1.86 MWe with a gasification capacity of 1.5 Mg.h-1 of pellets was assessed. This low scale gasifier was selected for this study considering that the required biomass supply could be satisfied within a radius of 5 km from the plant. Power and heat efficiencies were obtained from local suppliers and checked with bibliography resulting figures of 28 % and 53 % respectively. All calculi were done using Microsoft Excel including our own data when available or from other sources otherwise.

Energy balance

Energy inputs (EI) per Mg of pellet (dry basis) of each stage (Figure 3) were considered and Energy Return on Investments (EROI) was calculated using Equation 1:

For harvest and shipping stages, we estimated the EI considering diesel requirements, which were consulted to custom chopper operators, and shipping service providers. Biomass drying EI requirements were obtained by calculating energy needed to evaporate water (water evaporation latent heat) to reach a moisture content of 15 % necessary for pellet production. The biomass moisture content was modeled at 40 % considering that this value is a common figure for this species. We considered 50 % efficiency of the rotary dryer. The heat required for drying was obtained from the combustion of syngas as consulted to the supplier of the gasifier. Following Zhu & Zhuang (2012), we considered 50 kwh per Mg of dry matter for miller operation. Pelletizing stage EI was obtained according to a local company. S. argentinensis lower heating value was measured using an isoperbolic calorimeter (Parr 1261®). This type of calorimeters reduces heat exchange between the cell where the sample is burnt and its surroundings (Giraldo-Gutierréz & Moreno-Piraján, 2005).

Economic assessment

Projections were made in real terms at constant currency (May, 2016), before taxes accounting annual periods in a 20 years horizon. The opportunity cost or discount rate is a real annual rate composed of the sum of (i) risk-free interest rate, which considers the yield of the US Treasury bonds 2.1 %; and (ii) a project risk fee for which Argentinean country risk was assumed 6.9 %. Accordingly, the opportunity cost was set at 9 %.

Economic costs of power generation

We accounted the cost of power generation of the CHP plant and assessed the relative share of each item from the production process, grouping them according to the following classification of the Total Cost (TC):

TC = E + D + OC (2)

where: (E) Expenditures on services and nondurable goods, which include biomass chopping and shipping, labor, O&M of goods, fixed costs and other minor costs; (D) Depreciation of durable goods (machinery and buildings), and (OC) Opportunity Cost (remuneration of invested capital).

Financial assessment

Project feasibility was analyzed from a private investor point of view and determined by comparing the profitability against the capital opportunity cost. We performed an investment cash flow for the implementation of the project over a 20 years planning horizon, including all investments on durable goods (land, improvements, and machinery) and in working capital required for biomass chopping, shipping, drying, pellet production, storage, gasification, and heat and power generation.

The considered selling price of energy was 113 USD.MWeh-1 according to local legislation (Argentinean Law 26.190 passed the congress in December 2006 and was modified in September 2015). Heat obtained through cogeneration was valued in terms of the cost of natural gas savings on an equivalent energy basis: 0.28 USD.m-3 according to Argentinean natural gas distributors. Net Present Value (NPV) was estimated for two scenarios considering different prices of natural gas: (i): business as usual Scenario (BAUS) with natural gas price of 0.28 USD.m-3; and (ii): alternative scenario (AS) considering an international natural gas average price of 0.47 USD.m-3 (Asociación de Distribuidores de Gas, 2015).

The BEPE (Break-Even Price of Energy ) (Equation 3) was calculated for BAUS and AS modifying the methodology proposed by Garcia-Barberena, Monreal & Sánchez, 2004):

where: (NPV) Net Present Value according to Caputo et al. (2005), (n) number of years of the planning horizon (20 years); (I 0 ) initial investment, (R(BEPE) i : cash flow in the year i in real money units, and (d) discount rate (9 %).

We considered that 60 % of ANPP of S. argentinensis could be harvested and bought to farmers with a fee established at 50 % of the rental value of land used for beef cattle production (25 kg of meat per ha per year). As there is no experience of S. argentinensis harvest (at least as a standard service), we have considered an estimated fee provided by a custom chopper operator associated to the «Cámara Argentina de Contratistas Forrajeros». Shipping fees were consulted at Confederación Argentina del Transporte Automotor de Cargas (2015). Estimated investments required for equipment as well as its operation and maintenance (O&M) costs were consulted to local suppliers. Fixed costs of the plant were estimated considering: (i) professional advice; and (ii) administrative expenditures including mobility, communications, insurance, and contingencies.

From the estimated NPV figure, a sensitivity analysis was performed to meet the uncertainty of power efficiency, power selling price, harvest yield, chopping and shipping fee, investments, heat efficiency, natural gas price, fixed costs, discount rate and biomass fee. For each variable, we calculated the deviation in the NPV for a 10 % reduction of thevariable.

Results and Discussion

Energy balance

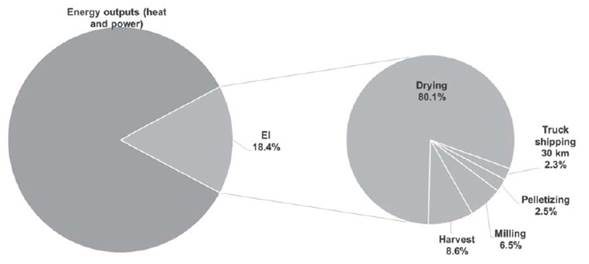

The lower heating value of S. argentinensis is 5170 KWh*Mg-1. Energy inputs of the entire process were 770 KWh.Mg-1 (18.4 % of energy outputs) while heat and power figures were 2740.1 and 1447.6 KWh.Mg-1 respectively (Figure 4). The main energetic input corresponds to the process of biomass drying, followed by harvest and milling. For obtaining 1 Mg of pellet, 428.57 kg of water needs to be evaporated within the dryer, which implies 617.6 thermal KWh. Noticeably, the hot point of EI was the drying stage; hence a cheaper drying process (in terms of EI) should be assessed, such as mowing for producing round bales which would allow drying biomass at farm with solar energy, providing a dryer biomass to the gasification plant. EROI of the model was 5.43, which implies that for each unit of energy invested, it is possible to obtain 5.43 units. Our results are promising when compared to other alternatives such as corn bioethanol in the USA with figures of 3.84 (Pimentel & Patzek, 2005).

Figure 4: Energy Inputs (EI) to energy outputs ratio and breakdown of energy inputs of pellet production.

Besides the good energetic performance, this alternative would not alter actual land use, hence ecosystem services of rangelands such as carbon sink and biodiversity would remain the same (Sosa, 2015) and the negative impact on the environment and human health of wildfires would be avoided. Moreover, this proposal would replace non-renewable fossil fuels aiding to achieve Argentinean energy selfsufficiency. Subsidizing fossil fuels discourage investmentsin renewable energies, hindering its development.

Even though carbon emissions from wildfires would remain equal to that of syngas combustion (as in both scenarios, the emitted carbon was fixed from the atmosphere by photosynthesis), in the latter case, the particulate matter wouldbe controlled by filters in the CHP plant. Jungbluth et al. (2007) reported substantially lower particulate matter and NOx figures derived from wood feedstock syngas production than those calculated for wildfires (Akagi et al., 2011). Furthermore, sing S. argentinensis pellets for CHP would save carbon emissions from displaced fossil fuels used either for heat or power generation. These advantages of the proposed bioenergy production system will favor exports to other countries. Therefore, NOx, SOx, CO2 balances and particulate matter emissions should be accounted in future research to assess the environmental impact of the proposed project.

Our aim is an alternative use of this feedstock for both, bio-energy and livestock production, since data from other authors (Bissio & Luisoni, 2014) as well as from our research group (Castagnani et al., 2016) show that leaves of Spartina argentinensis that continue growing after biomass harvest, have better forage quality. Therefore we propose integrating mowing at the end of winter with a period of grazing during the spring and summer seasons. Two years of grazing and resting periods between successive biomass removals would result suitable in order to maintain productivity as well as biodiversity. Considering that: i) within these ecosystems, it has been reported the presence of nitrogen fixing Cyanophyceae, mainly of the genera Nostoc, Anabaena, and Oscillatoria (Di Domenica, Petenello & Feldman, 2013), ii) as most C4 grasses, S. argentinensis presents high nitrogen use efficiency, iii) such ecosystems are frequently subjected to prescribed burn with no nitrogen remaining in ashes, iv) only some minerals such as K2O, P2O5, CaO, and MgO remain within ashes after prescribed fires (Jozami, Sosa & Feldman, 2003) and v) ashes and biochar produced during gasification can be returned back to the soil; we hypothesize that our proposal would be more sustainable than the business as usual scenario which consist on frequent prescribed fires.

Economic costs of power generation

Economic costs shares of producing 1 MWh are highlighted in Figure 5. The chopping fee was the most expensive stage followed by labor and opportunity cost of capital. Rentizelas et al. (2009) found a similar share of biomass logistic costs. As stated before, this analysis did not consider taxes; hence, policy makers should consider reducing taxes for RE projects to stimulate such investments. The opportunity cost of capital and O&M costs took a significant share as well as amortization and improvements, and even though shipping costs were also important, it is necessary to consider that this fee can vary significantly depending on the moment of the year associated with the high demand of trucks for crops during periods of harvest. Biomass density, and vehicle capacity variability could increase shipping costs as well (Caputo et al., 2005). Furthermore, this fee is tied to the highly volatile price of fossil fuels.

Financial assessment

Major costs of the modeled processes for CHP production have been assessed for S. argentinensis considering the stages of biomass clipping, shipping to plant, biomass handling, drying, biomass pelletizing, pellet storage in silos and pellet gasification. The initial investment was close to 5.3 million USD (Table 1) corresponding almost 60 % of it to the pelletizer and gasifier CHP plant, which is consistent with figures proposed by Ouyang & Lin (2014) who pointed out that power generation facilities account for 60-80 % of the total construction investment. This investment is similar to the 6.6 million USD obtained by Penniall & Williamson (2009) for a sawmill CHP plant in New Zealand, and lower than the estimations presented by IRENA, 2015). O&M of capital accounted 24.3 USD.MWh-1, 85 % of it represented by the gasifier and the pelletizer which are similar to figures reported by IRENA, 2015). More than one million USD are required as working capital for running the plant during the first year. The investment for land acquisition was low as land prices in the location where the plant would be set are low due to its low productivity. However, near the S. argentinensis communities, there are medium size urban areas with power demanding industries, such as slaughterhouse, dairies and sunflower and soybean oil processing plants.

The BEPE was obtained for the BAU and the AS scenarios, resulting in figures of 149 and 126.2 USD.MWeh-1 respectively. These figures are consistent with the range of BEPE reported by the International Energy Agency for biomass derived electricity, where an exhaustive data review of electricity production costs of different generation alternatives has been presented (IEA, 2010). The NPV of the project resulted -4.4 and -1.6 million dollars for the BAUS and AS respectively. Hence, by only increasing the price of natural gas, a significant improvement of the economic results of this type of projects would be addressed. Pantaleo, Pellerano & Carone (2009) reported that without feed in tariff (FIT) set by local legislation in Puglia (Italy), NPV of fiber sorghum pellet gasification would result negative and the internal rate of return would be circa 1 %. According to our results, S. argentinensis gasification for CHP will require initial stimuli by policy makers. FIT is widely recognized as the most efficient tool in order to incentive RE investments with negative results considering that production costs should decrease as experience with this technology accumulates. Couture & Gagnon (2010) reviewed different alternatives of FIT. Furthermore, CO2 credits will soon become another tool to incentivize RE productions technologies such as gasification (IRENA, 2015).

Sensitivity analysis assessed the change of NPV over a 10 % decrease of most important variables. The most sensitive variables were power efficiency, power selling price, chopping fee, Mg harvested per ha, and investments (Figure 6) with figures greater than -30 % for the first two variables and circa 20 % of NPV variation for the others. Discount rates did not affect markedly the NPV which implies that a variation of it will not impact strongly on the cash flow of the project. Moreover, considering that such investments are mainly accomplished supported by bank loans, this data result valuable for a private investor. The harvest should receive special attention as such variable has high temporal and spatial variability. Plots with high biomass should be selected for harvest and chopping efficiency and should be monitored in order to increase biomass yield as much as possible. As previously reported, chopping of S. argentinensis was modeled; as such grass has not been chopped yet by any custom chopping company though we could mow and hay it in a lowland rangeland of Santa Fe province. Chopping fee should also be a point to consider regarding the fact that it is not yet a standard service, and that the fee considered here was an approximation consulted to a chopping company.

Caputo et al. (2005) highlighted that logistic costs of biomass can vary significantly. In our analysis, harvest yield and chopping fee were the only logistics variables with important effects on NPV. However, it should be noted that in this analysis, only a 10 % decrease of each variable was assessed, while the natural variation of some variables can be significantly higher. Even when natural gas price sensitivity did not result high, it is, though, an important variable to consider as the price in Argentine results remarkably lower than that of other countries as a consequence of high governmental subsidies. In line with this, Moon, Lee & Lee (2011) reported a high sensitivity of internal rate of return to heat selling prices for a gasification plant assessment in Korea.

Climate change is one of the main topics on the agenda of policy makers worldwide. RE will play a key role in the mitigation of climate change by reducing the GHG emission when compared to fossil fuels. Carbon balance of each bioenergy source will condition its acceptance for world trade, while will limit the possibility to apply for carbon credits depending on the GHG emission reduction of the assessed feedstock. There are no studies of carbon balance from S. argentinensis but we sustain that considering its high yield, even under drought conditions, and the low energy costs for harvesting, transporting and conditioning of biomass, carbon balance might be close to neutrality.

Half of the power generated in Argentine derives from thermal combustion of natural gas (Argentina. Ministerio de Energía y Minería, 2016). A significant proportion of this fossil fuel needs to be imported at high costs affecting negatively the commercial balance. The industrial sector consumes circa 44 % of national electricity demand. Therefore, a substantial figure of national imports could be reduced by generating power with available feedstock, using species with characteristics similar to that of S. argentinensis like Spartina densiflora, Panicum prionitis, and Paspalum spp.

The economic results of this research show that under the assessed conditions (May 2016 Argentinean energy market), the production of heat and power from S. argentinensis is not profitable; moreover, it would generate significant losses to the private investor. In line with this, there are no reported examples of private investments in second generation biofuels in Argentina. To overcome this issue many authors agree that FIT is the best policy available to stimulate investments in RE. Another policy that would enhance the economic results of this activity would be to cut subsidies to natural gas in order to reduce the BEPE as the heat generated from the biorefinery would be more valuable.

Conclusions

The attainable energy balance estimated from the production of heat and power via gasification of pellets of S. argentinensis denotes a high potential for this proposed bioenergy production system and carbon credits not accounted here could improve the NPV of the investment. Grass haying allowing field drying up to 10-15 % moisture content without any energetic or monetary cost would help reducing energy inputs.

There would not be a change in land use which has negative impacts such as biodiversity losses and increases in CO2 emissions, as S. argentinensis communities would remain the same while being used for bioenergy production. Positive externalities would arise from the settlement of this project: employment of local people; rural development; and food and energy security.

The Argentinean administration that began the 10th of December of 2015 claimed that substantial changes in the policy of the energy market should be made. Parallel to circa 60 % devaluation, they focus on significant and progressive increases in electricity and natural gas prices by cutting federal subsidies and supporting bioenergy production. The devaluation reduces the cost of labor while other cost components increased in local currency as well as the selling price of heat and power, hence reducing the BEPE here assessed. Therefore, this scenario will strongly encourage private investment in this crucial sector for national energy self-sufficiency.